Materialization of 115C8 and 18F44

|

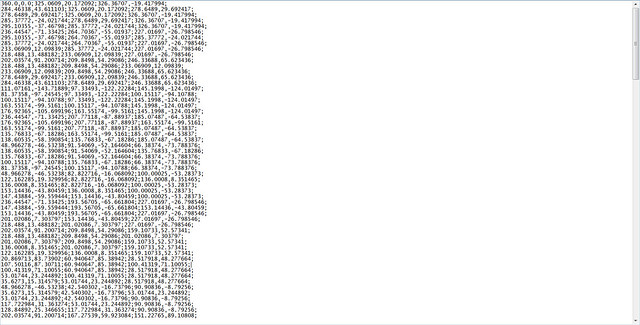

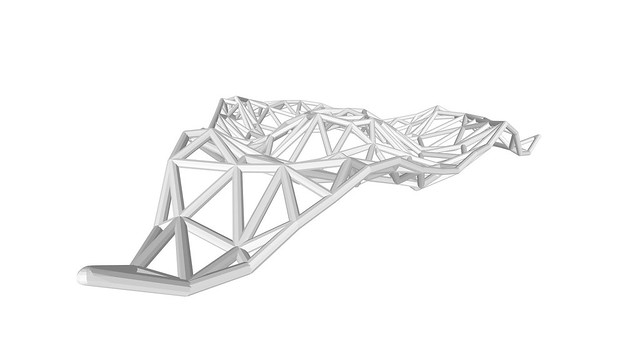

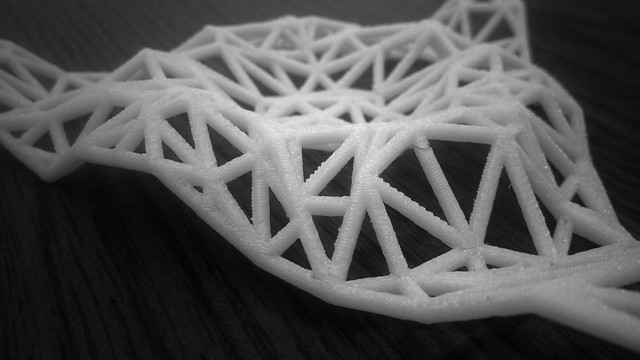

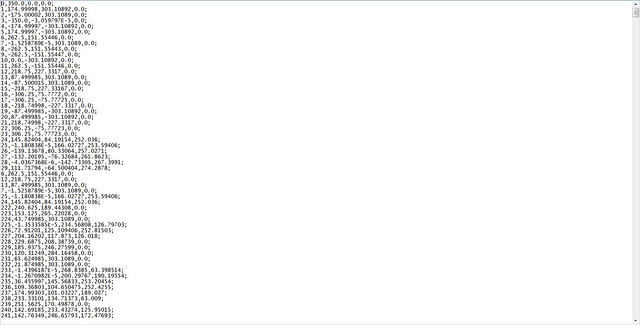

Created in Oct.2012 As the independent study project of my first semester at RPI, I fabricated a copy of 115C8 and 18F44‘s first demo version using fused deposition modeling technology, or mistakenly referred to as 3D printing by most people. Both structures were exported with a lower recursive level because of the facility’s limitation. Due to the edge-based structures of both creatures, I used HE-Mesh library developed by Frederik Vanhoutte to generate struts and meshes around each edge, thus creating a lattice-like object. The process was divided into two steps. First was exporting all pairing vertices, which connect with each other to form edges, and their coordinates. Filtering repetitive pairs was also required in this procedure as the structure’s recursive feature would sometimes result in the situation that parental segments and descendant segments coincide as one. Second was importing the optimized vertices data and re-generate the structure, which is ready to be exported as stl.

|